Різниця між ремінним приводом ГРМ і гвинтовим приводом лінійного модуля

Linear slide modules can be divided into two categories according to their working principles: screw drive and timing belt drive. Timing belt modules and screw modules have their own advantages in durability. The specific choice depends on the usage scenario and needs. Timing belt modules usually have higher speeds and are suitable for occasions that require rapid movement and positioning, while screw modules have higher rigidity and precision and are suitable for occasions that require large loads and high precision.

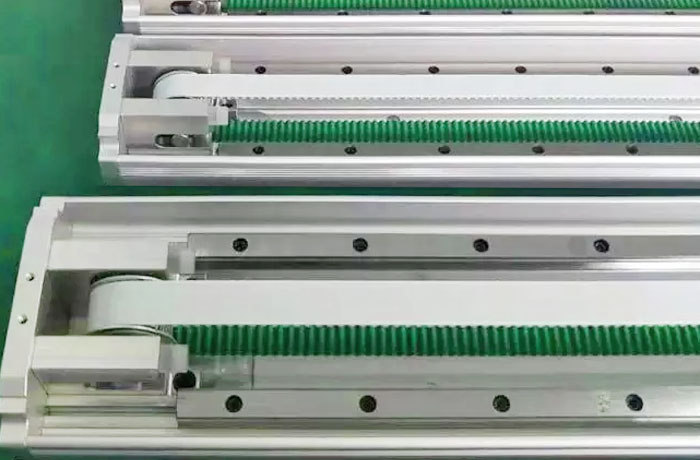

Timing beltmodule

The meshing transmission between the timing pulley and the timing belt transmits power to achieve linear motion. The timing belt module uses the tooth shape of the timing belt to correspond to the tooth shape of the timing pulley to achieve precise transmission.

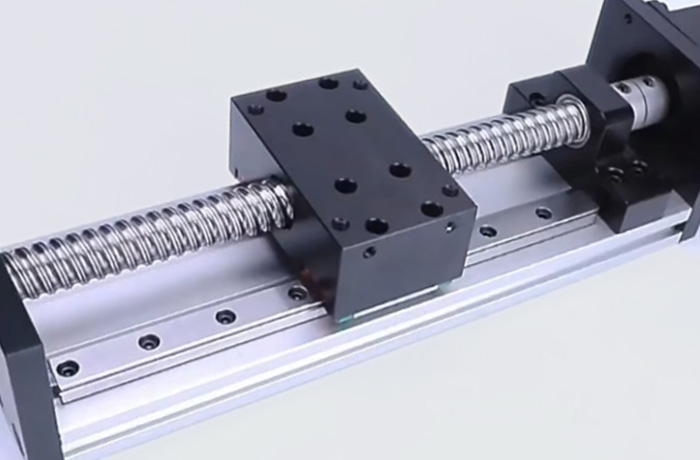

Screw module

A transmission mechanism that converts the rotational motion between the threaded screw and the nut into linear motion. The ball screw module uses the rolling of the ball between the screw and the nut to reduce friction and improve efficiency.

The timing belt module and screw module in the linear module can be selected according to the following comparison and needs.

1. Precision:

Screw module: It has high positioning accuracy and repeatability. The high precision of the screw module is mainly due to its high rigidity and low friction characteristics, and is suitable for occasions that require high-precision positioning.

Timing belt module: The accuracy is usually lower than that of the screw module, and it can also meet the accuracy requirements of most industries. The accuracy of the timing belt module is mainly affected by the manufacturing and installation accuracy of the timing belt and timing pulley. To ensure the high-precision operation of the module, it is necessary to select manufacturers with advanced production processes and strict quality management systems to use high-quality timing belt and timing pulley when purchasing.

2. Speed:

Screw module: The speed is relatively slow, especially under high-precision requirements. But there is no critical speed limit, which is suitable for applications that require high-precision positioning.

Timing belt module: The speed is fast, and the maximum speed can reach 2~3m/s, which is suitable for applications that require high-speed movement.

3. Load capacity:

Screw module: It has a large load capacity and can withstand large loads, which is suitable for heavy machinery and equipment.

Timing belt module: The load capacity is relatively small compared to the screw module, and it is suitable for occasions with light loads.

4. Noise and maintenance:

Screw module: It is noisy during operation and may require more maintenance.

Timing belt module: It has low operating noise and relatively simple maintenance.

5. Cost:

Screw module: The cost is high, especially the screw module with high precision and high load.

Timing belt module: The cost is low and it is suitable for occasions with limited budget.

6. Stroke:

Screw module: The stroke is relatively short, but complex motion control can be achieved through multi-axis combination.

Timing belt module: The effective stroke is large, which can reach several meters or even longer.